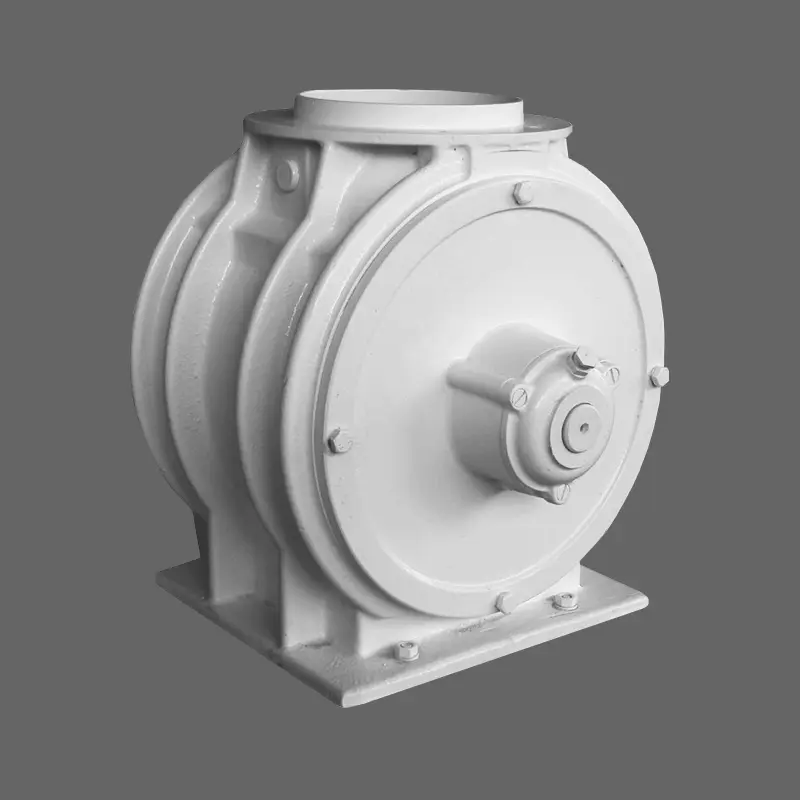

The casing is equipped with an inlet and outlet throat. On the sides, it is closed with two lids with hubs for bearings and shaft sealing of the sealing roller, which rotates in the casing.

The sealing roller is equipped with six ribs, which create pockets and are connected to the shaft with a conical pin. The shaft is stored in two ball bearings. The drive is standardly equipped with an MRT worm gear motor through a flexible LKN 30 coupling, which is also used to connect sealing devices with each other and with inserted shafts. For end sealing devices, it is possible to use speed control with an inductive probe.

The material falls through the inlet throat onto the rotating sealing roller and fills its pockets. The rotation of the roller transfers it to the lower outlet throat, where it proceeds to the subsequent technology. In doing so, it acts as a seal between the pressurized and unpressurized space.

Sealing devices TU200 and TU250 are among our traditional products. Years of proven and reliable design provide a high level of reliability in demanding operations

With us, you won't pay more than you have to. We constantly work to offer our products at fair prices.

We can respond flexibly to any demand. Contact us. We will prepare a non-binding offer tailored to your needs.

Sealing roller diameter: 200 mm

Flange type: upper and lower square flange

Theoretical output: 18 m3h-1

Speed: 70 min-1

Speed control probe (optional): Siemens 872C D8NP18-E2 min-1

Weight without drive: 43 kg

Weight with drive: 65 kg

Power consumption: 0,75 kW

Gearbox: MRT-70-20-A/B3-80/100-0,75/4p-230/400-50 (TOS Znojmo)

Nominal current: 1,86 A

Power consumption: 1,10 kW

Gearbox: MRT-70-20-A/B3-90/115-1,1/4p-230/400-50 (TOS Znojmo)

Nominal current: 2,65 A

Sealing roller diameter: 250 mm

Flange type: Upper flange round-shaped, lower flange square-shaped

Theoretical output: 30 m3h-1

Speed: 70 min-1

Speed control probe (optional): Siemens 872C D8NP18-E2 min-1

Weight without drive: 60 kg

Weight with drive: 83 kg

Power consumption: 0,75 kW

Gearbox: MRT-70-20-A/B3-80/100-0,75/4p-230/400-50 (TOS Znojmo)

Nominal current: 1,86 A

Power consumption: 1,10 kW

Gearbox: MRT-70-20-A/B3-90/115-1,1/4p-230/400-50 (TOS Znojmo)

Nominal current: 2,65 A

Gama Pardubice s.r.o.

Holandská 528

533 01 Pardubice

Czechia

phone: +420 466 670 070-2

e-mail: info@gama-pardubice.cz